CHAPTER 15: Transition Begins

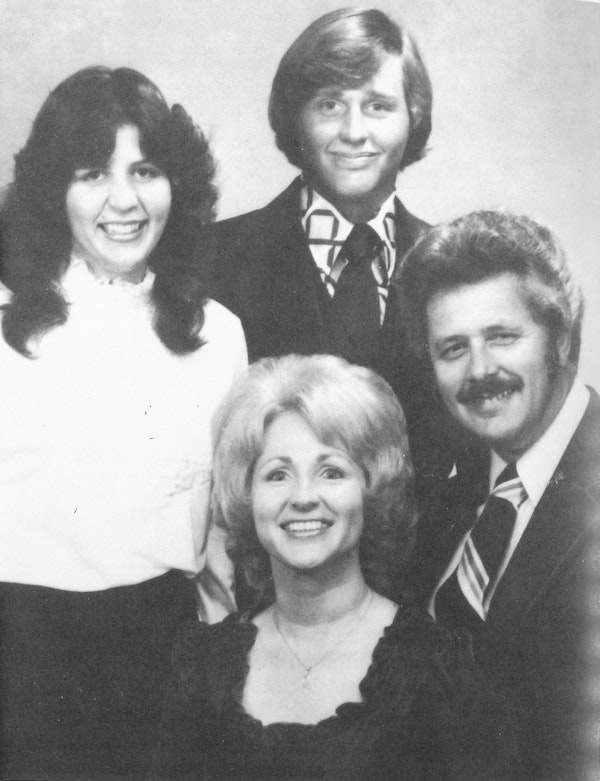

In the timeline that stitches it’s way through the 30-year corporate history of Buck Knives, the year 1975 is memorable for two principal reasons. First, net profits hit a record high. Second, and not coincidentally, 1975 was the year Al Buck began preparing for retirement.

"It wasn't like I woke up one day and decided it was time to retire, but as time went on I found myself giving it more and more thought," Buck confided.

"The company was doing well. Ida and I still had our health, and we both liked to travel. I suppose things sort of came to a head in 1975, the year I turned 65. I still wasn't sure when I wanted to leave, but I began getting the company ready for the day I did."

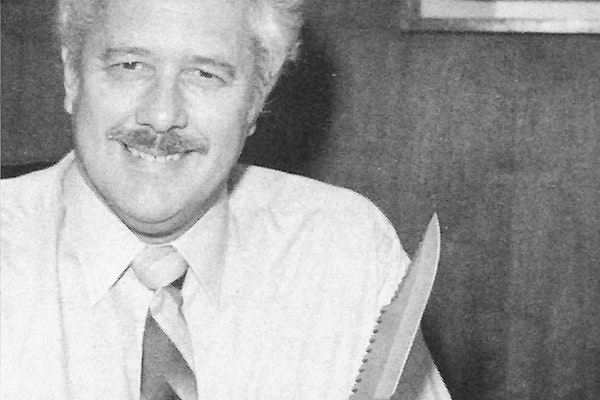

The first major step in the transition process was the promotion of Chuck Buck to the position of executive vice president in 1975.

Chuck had been heir apparent for years, but the transition still was not without difficulties. Craig and Ham, for example, had helped found the company. For 15 years, they had served as the firm's senior executives. Now, suddenly, they found themselves answering to Chuck Buck, and all three men needed time to adjust.

"It was an unsettling time," Chuck Buck recalled. "I had a lot of respect for those men.

At the same time, I was 20 years younger, had worked in every area of the company, and felt I had something to offer, too.

"I wouldn't say they resented me, personally, but I think they resented the situation, and that led to some tension now and then."

Craig, who was still vice president in charge of manufacturing at that time, began preparing for his own retirement in 1977. Specifically, he took day-to-day command of the Helix Manufacturing Company, the Buck affiliate responsible for stamping out blades. He also became an executive adviser to the corporation.

Craig's advice was freely offered, and freely sought. Al Buck's principal partner since 1960, Craig had played a major role in the growth of the company and, even in "semi-retirement," his input was invaluable.

Not surprisingly, the continued growth of the company led to increased problems as well as increased sales.

Some of these difficulties stemmed from breakdowns in communication and coordination among the various components of the expanding operation.

"I'm sure all firms experience growing pains, and even though we tried hard to encourage teamwork and togetherness, it was difficult to keep everyone pushing in the same direction," Al Buck admitted.

"Not only did we have a variety of different divisions, several of those groups were located away from the main plant, and they all developed their own way of doing things. It was no one's fault. I think everyone had good intentions.

"Good intentions or not, by 1977 we realized we had some communication problems that needed some serious attention," he concluded.

After deliberation, the board of directors requested a feasibility study to learn if productivity might be enhanced by bringing the various arms of the company back under one roof.

In all, Buck was occupying seven different buildings. In addition to corporate

headquarters, the company leased six separate facilities to accommodate its various components.

The fixed-blade, lockblade, slimline, pocket knife, grinding and warehouse units all operated from different locations.

The Helix Manufacturing Company stamped blades at still another location in El Cajon, and Buck's other affiliate - Merit Products - produced the sheaths in Chula Vista, many miles to the south of the headquarters building and its array of satellites in the El Cajon valley.

"When we began decentralizing, necessitated by growth, we didn't think it would be a problem," Al Buck said, as he thought back over the stages of growth the company had gone though. "But over the course of time, we gradually lost that sense of common purpose we had developed earlier. Managers began struggling for turf. Employees began developing loyalty to their units instead of to the company itself."

Buck's consultants concluded that decentralization had begun to hurt the company's performance. A subsequent study outline the long-range requirements the firm should seek in a new facility.