CHAPTER 12: GEARING UP FOR MASS PRODUCTION

Sales and profits grew steadily throughout the 1970s, not because Buck introduced spectacular new products, but because it spent most of the decade streamlining the production of those it had.

New machinery, methodology and systems of delivery were tested, reviewed and refined until they were adopted or simply abandoned.

"Until 1970, we solved most of our serious problems by adding people," Ham confessed. "We did practically all of the intricate work by hand.

"As time went on, however, we all saw the need to mechanize. If we were going to grow, we had to produce more units, and it was obvious that we had to build them more efficiently," Ham continued.

"In one respect, I guess it was a pretty uneventful decade. We didn't introduce anything terribly new or exciting. But it was an important time for the company because we learned how to mass produce knives.And that knowledge proved crucial when the product line expanded again in the '80s."

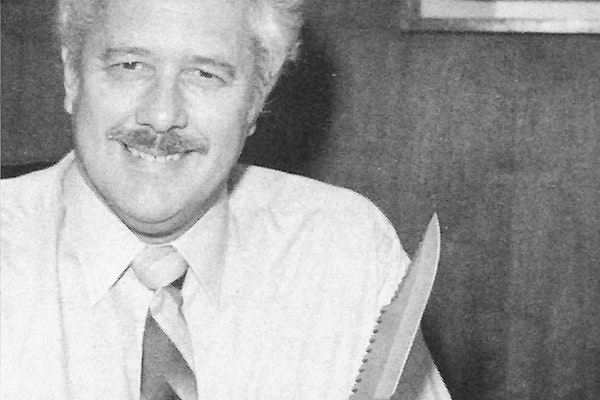

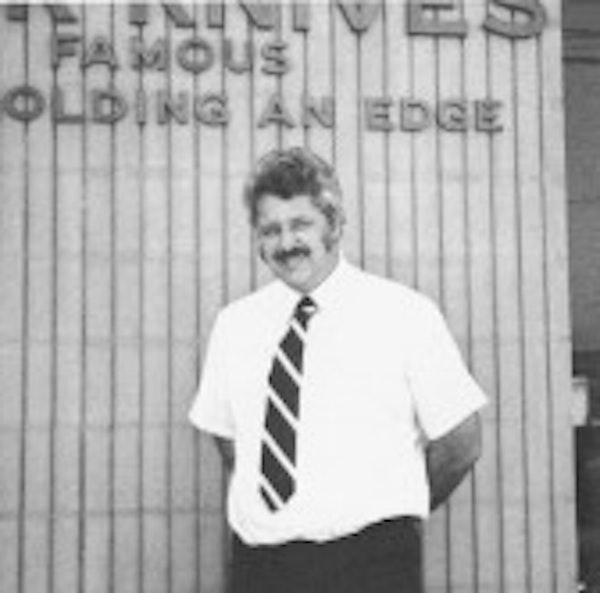

A key figure in this process was Chuck Buck, Al's oldest son. Born May 13, 1936, in San Diego, Chuck was a familiar face throughout the development of the company.

As a boy, Chuck had done odd jobs for his grandfather, Hoyt. As a teenager, he operated the family lawnmower shop that helped keep the knife company in business.

In 1961, nine months after his discharge from the U.S. Navy, Chuck was named to the corporation's board of directors.

But the 25-year-old Buck was content to keep a low profile. During the '60s, he was more manager than administrator, yielding the larger decisions to his father and Al's two principal associates, Howard Craig and Don. As time went on, Chuck Buck's stature began to grow. In 1970 he was named corporate vice president for manufacturing, fully involved in all aspects of the process, from purchasing to personnel to packaging.

"Chuck never graduated from college, but he always had gifts you could never get from a book," Al Buck said. "He had a great way with people, for one thing. He had good business instincts. And he was a tenacious problem-solver. Chuck was stubborn enough to keep working at the problem and creative enough to try different solutions until he found one that worked

"I knew the day we started the company that someday Chuck would take my place. And never, not even for a moment, was I tempted to change my mind."

Chuck's younger brother, Frank Donald Buck, also played an important part in the growth of the company. Warm, good-hearted and well liked by all who met him, Frank directed the Folding Hunter program for a time, and later became Customer Service Manager. Tragically, however, he died in an automobile accident in July 1974.

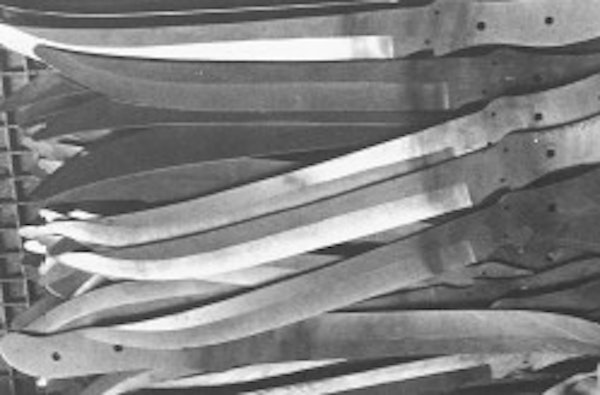

As Buck Knives sought ways to streamline production, it also took steps to control the cost, quality and accessibility of fundamental supplies.

Helix Manufacturing Company was established by four Buck stockholders, and Helix was immediately assigned the task of stamping out blades. They also established Merit Products to produce the leather sheaths that were packaged with Buck knives.

In 1981 Helix was acquired by Buck Knives and merged into the corporation, and moved physically into facilities near corporate headquarters in El Cajon.

Merit's name was changed to American Leathercrafters in 1984, and then was acquired by Buck in 1985. But it continued to function as a separate entity until 1989 when it was merged into Buck Knives.

With Buck's healthy growth through the '70s, the need for additional space was such that it leased six nearby buildings to house operations it could no longer squeeze into its own plant on Magnolia.