Our story, the story of Buck Knives is a story of a family that is proud of its roots, and remains dedicated to the same basic precepts that our founder, Hoyt Buck so clearly laid out many years ago.

It all began at the turn of the century when Hoyt, a teenage apprentice blacksmith created his first knife – a knife that led the way to the wide range of knives that proudly bear his name today.

Based on “The Story of Buck Knives… A Family Business”, written by Tom Ables, we’ll unfold our story, a century of Buck family history and business ventures that created our company.

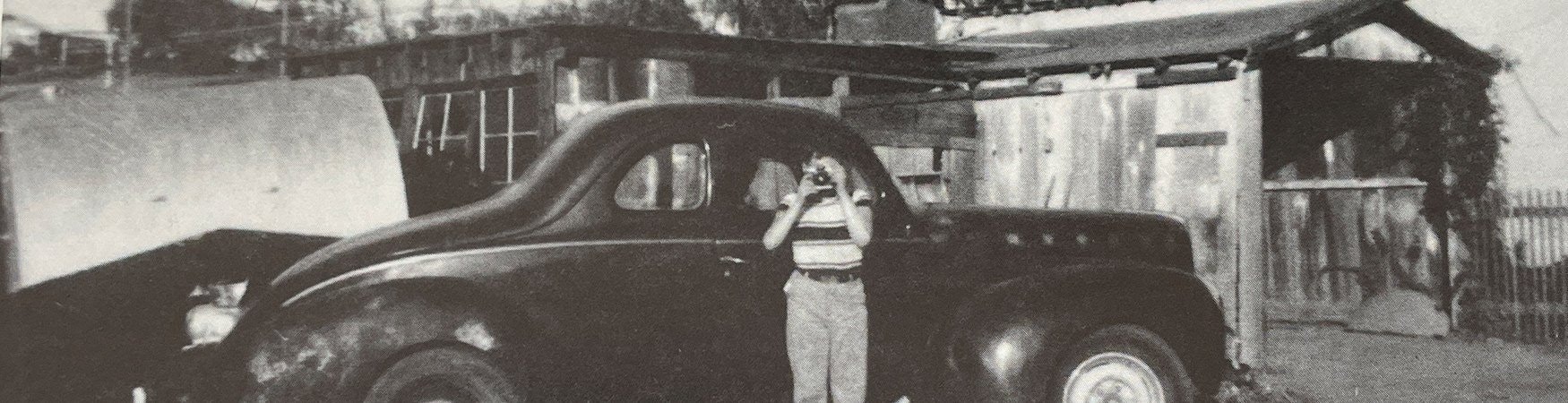

THE FIRST BUCK MANUFACTURING PLANT

It was somewhat surprising that Hoyt and Daisy’s journey ”home” to Washington was being routed through California.

Both of them had been in ill health. The pain in Hoyt’s stomach would later be diagnosed as cancer. Daisy had begun suffering from Alzheimer’s Disease.

Since both of them considered the Seattle area their home, and since several of their children still lived in Western Washington, their trip in the opposite direction, to San Diego, seemed puzzling.

But Hoyt Buck obviously had a plan. He was excited about rediscovering his knife making skills. He had his hands on something he knew was substantial. He had a legacy worth sharing with his sons. And perhaps sensing that time was beginning to run short, Hoyt Buck was determined to bestow the legacy on the eldest of those sons, the one living in San Diego.

Buck’s first “manufacturing plant” actually was a 10×12-foot lean-to, which he built by hand on the side of Al’s modest, one car garage on Moreno Boulevard. Always one to make the most of his ingenuity, Hoyt used some clay bricks he had found near the railroad tracks that ran behind the house. He mixed his own mortar.

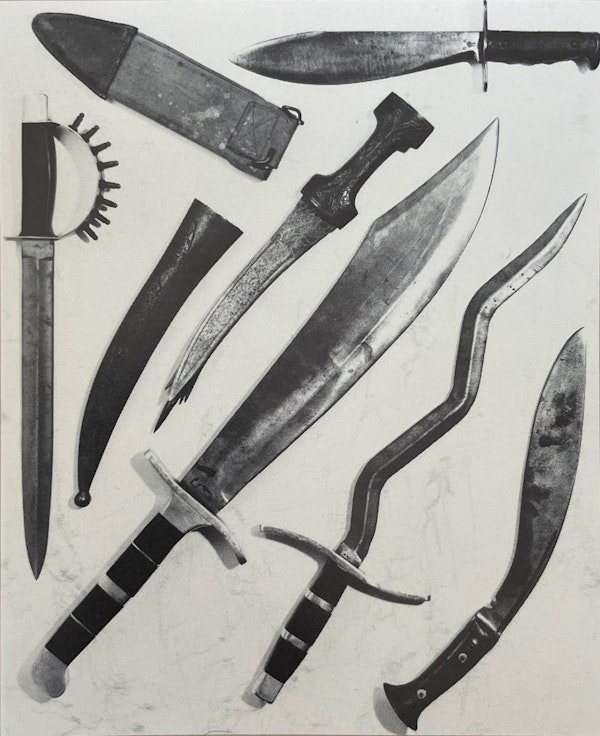

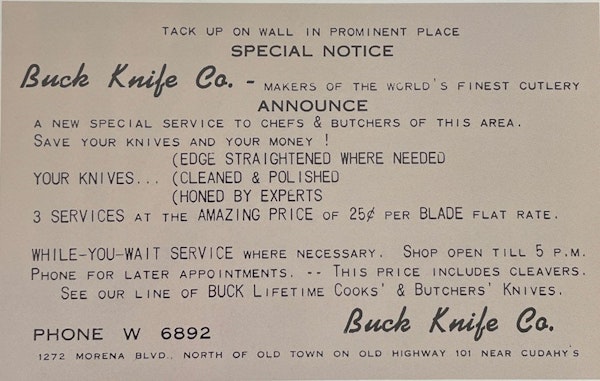

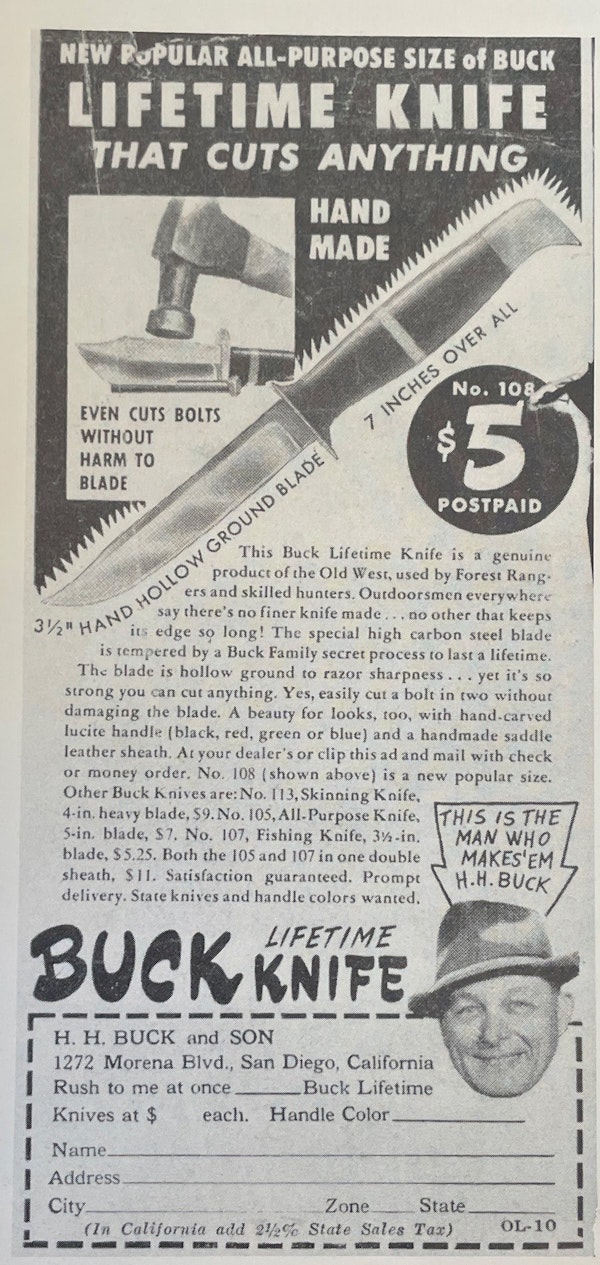

Then, with that work done, he was ready to begin making knives. He knocked on doors throughout San Diego. Each morning, he would approach the owners of butcher shops, restaurants and sporting goods stores, persuading them to place orders for Buck knives.

In the afternoon, he would return to his shop to fill orders he had taken earlier in the day. He could make only a handful of units a day, but there is no denying that H. H. Buck was in business! The Buck Knife company, in the real sense, was born there in that small lean-to in 1946.

Buck’s knives were all created from used metal files that had been discarded by Consolidated Vultee, the huge aircraft manufacturing plant that later became Convair. These worn-out files, with their heavy carbon content, were perfect for the toughness and edge-holding qualities that Buck required in his knives.

The teenage apprentice blacksmith of 1902 was finally capitalizing on his discovery, more than 40 years later.

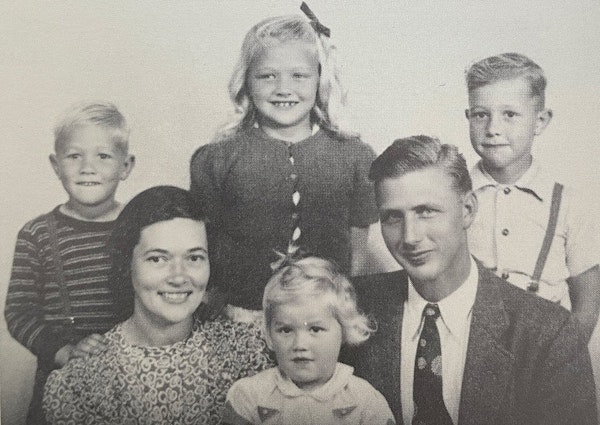

Determined to make the company grow, Hoyt Buck began urging his son, Al, to resign his job as a bus driver and join him in the knife business.

"To tell the absolute truth, I didn't want to do it," Al Buck recalled. "The knife business was hot, dirty, noisy, time-consuming work.

Still, in 1947, Al agreed to leave the bus company and he joined his father, fulltime. The resulting partnership was known as “H. H. Buck & Son,” but doubling the payroll did little to increase productivity.

“If Dad had known how much I had to learn about the knife business, he might have left me behind the wheel of that bus,” Al chuckled later. “He spent so much time teaching me what to do we produced fewer knives with two men than he’d been making by himself.

First, Al learned how to laminate the thin strips of Plexiglas used on the handles. He learned how to separate and drill the handles themselves. Later, he learned how to temper the blades so painstakingly sharpened by his dad.

“It sounded easy, but it wasn’t easy at all,” Al said. “We heated the blades with torches, and if the torch was too close, the blade got too hot. If you didn’t move the torch up and down the blade quickly enough, the heat wasn’t uniform.

“It was tricky, but if you did it just right the entire blade would turn a light tan color just before turning red, and at just that moment you plunged it into oil. Our tempering process was a little bit different than the one used by other knife makers, and it was one of the keys to our success.”

The last step in the education of Al Buck, knife maker, was to master the grinder, where Hoyt had crafted every blade the company had ever produced.

"For the first couple of years we were together, Dad did all the grinding," Al noted. "The grinder was his pride and joy, and he wouldn't let anyone near it. "

In 1948, though, Dad discovered he had cancer, and half of his stomach was removed. I think he realized then that his days with us were numbered,” Al continued.

“He also realized that I couldn’t make Buck knives until I learned how to grind the blades. I knew it was important to him. So, for an hour or two every day, I worked at the grinder, trying to get the hang of it.

“I can’t tell you how many blades I must have ruined in the process, but finally I thought I was ready.”

Al Buck stopped for a minute before continuing his telling of this story, savoring what must have been a very special memory.

"I remember calling Dad in and telling him to watch. I did one knife, and another, and another. Finally, his eyes started to sparkle, a smile came over his face, and he said, 'Now I almost feel my life is complete - my son can make knives!"'

Shortly thereafter, bowing to the wishes of Al’s brothers and sisters, Hoyt Buck moved from San Diego to Yakima, Washington. A year later, in 1949, he died of cancer at the age of 59.